Introduction:

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative; this is why the usage of electric actuators with electromagnets is an excellent alternative solution to improve efficiency, reduce costs, and enhance sustainability.

The Drawbacks of Compressed Air

High Energy Consumption

Compressed air systems are among the most energy-intensive equipment in manufacturing plants. It is estimated that producing compressed air accounts for 10-30% of a facility’s total electricity consumption. The inefficiency stems from the fact that only about 10-15% of the electrical energy used to compress air is converted into usable energy at the point of use; the rest is lost as heat.

Elevated Operational Costs

The inefficiency of compressed air translates into high operational costs. These costs are not limited to energy consumption but also include maintenance and repair expenses. Leaks in the system, which are common, exacerbate these costs, often going unnoticed and unaddressed for extended periods.

Maintenance and Reliability Issues

Compressed air systems require regular maintenance to function effectively. Components such as compressors, filters, dryers, and pipelines need constant attention to prevent leaks, contamination, and mechanical failures. This maintenance burden can lead to downtime and additional labor costs, impacting overall productivity.

Environmental Impact

The environmental impact of compressed air systems is significant due to their high energy consumption, which often relies on fossil fuels. The generation of compressed air contributes to greenhouse gas emissions and a larger carbon footprint. Reducing or eliminating compressed air usage can contribute to a company’s sustainability goals and regulatory compliance.

Electric Actuators as Alternatives to Compressed Air

Electric actuators offer a more energy-efficient alternative to pneumatic systems. They provide precise control, require less maintenance, and have lower operational costs. Advances in electric motor technology have made these solutions increasingly viable for a wide range of applications.

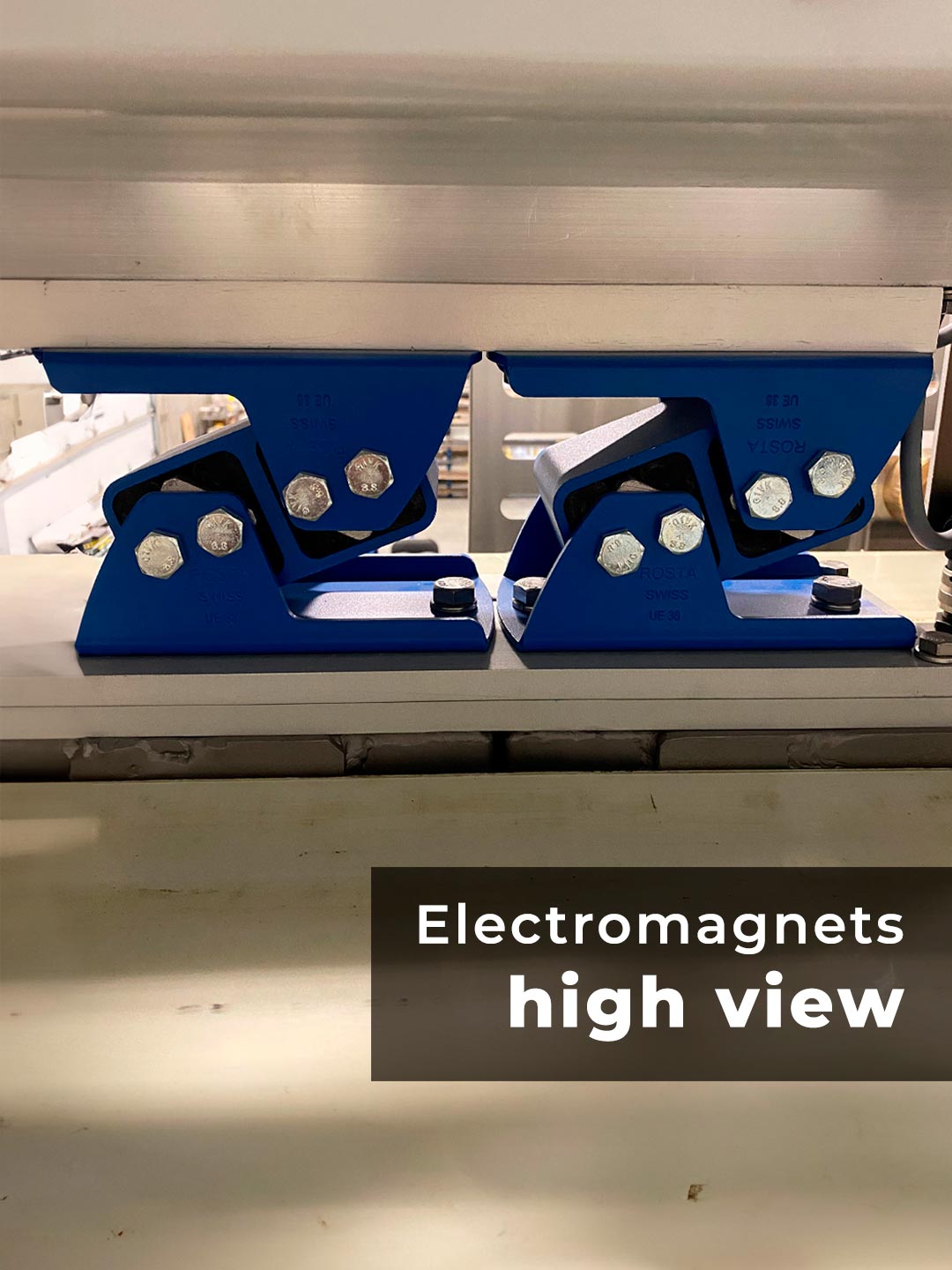

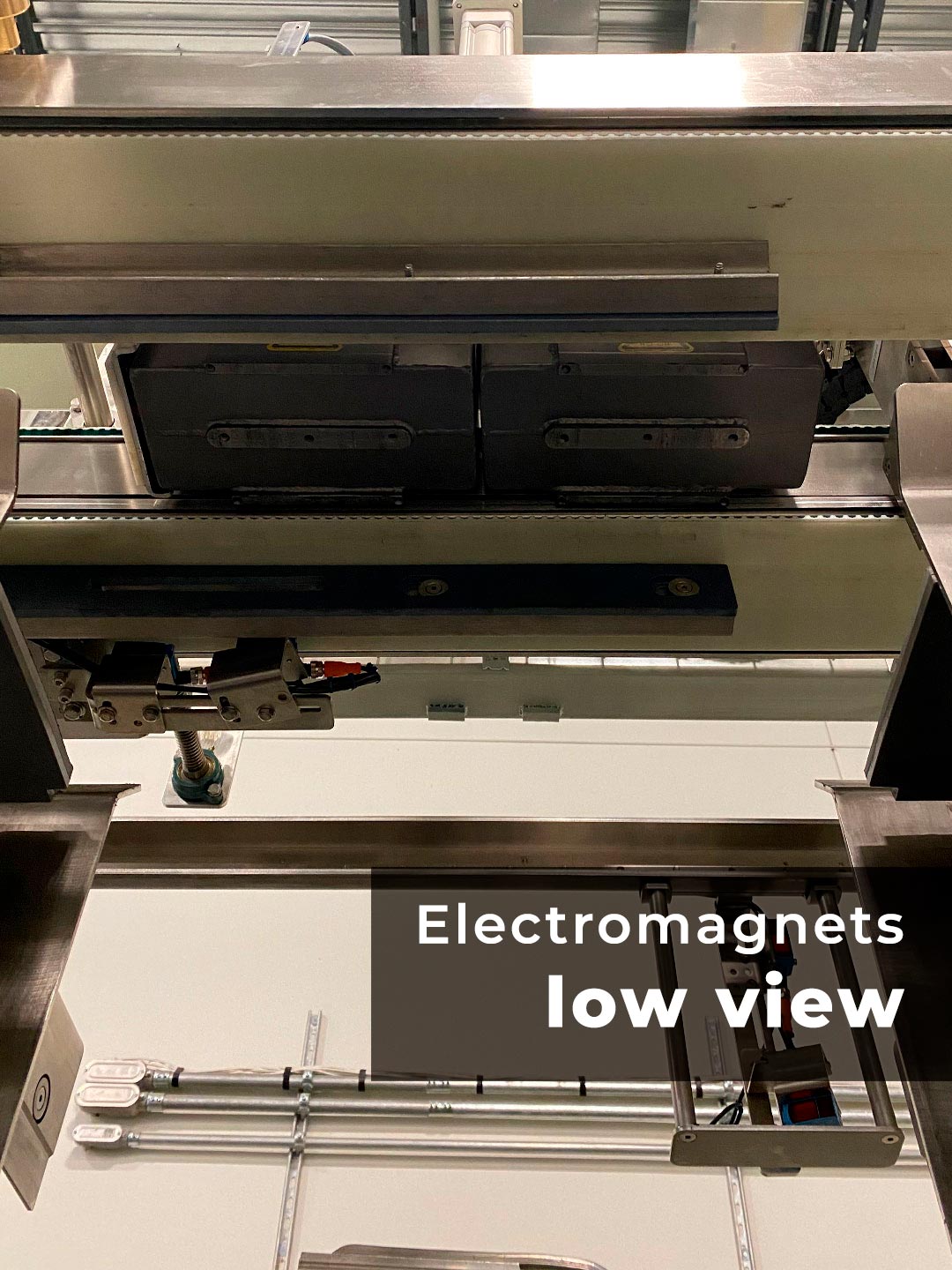

The electromagnet is a key element in many types of electric actuators, particularly in linear actuators and solenoid-based designs.

How Electromagnets Work in Electric Actuators

An electromagnet consists of a coil of wire through which an electric current is passed. This current generates a magnetic field, which can attract or repel a ferromagnetic object, creating motion. In the context of an electric actuator, this motion is harnessed to move a load or to control a mechanism.

Advantages of Using Electromagnets in Electric Actuators

- Precise Control

Electromagnets provide precise control over motion, enabling fine adjustments and accurate positioning. This is essential in applications where precision is critical, such as in robotics, automation, and medical devices.

- High Speed and Responsiveness

Electromagnets can switch on and off rapidly, providing high-speed actuation. This responsiveness is beneficial in dynamic environments where quick adjustments are necessary.

- Reliability and Durability

Electromagnetic actuators tend to have fewer moving parts than other types of actuators, which can enhance their reliability and durability. This makes them suitable for long-term use in demanding applications.

Conclusion

The bakery and food industry, like many other manufacturing sectors, heavily relies on compressed air systems due to their perceived convenience and energy capabilities. However, the significant drawbacks associated with compressed air—such as high energy consumption, elevated operational costs, extensive maintenance requirements, and environmental impacts—necessitate a re-evaluation of its use.

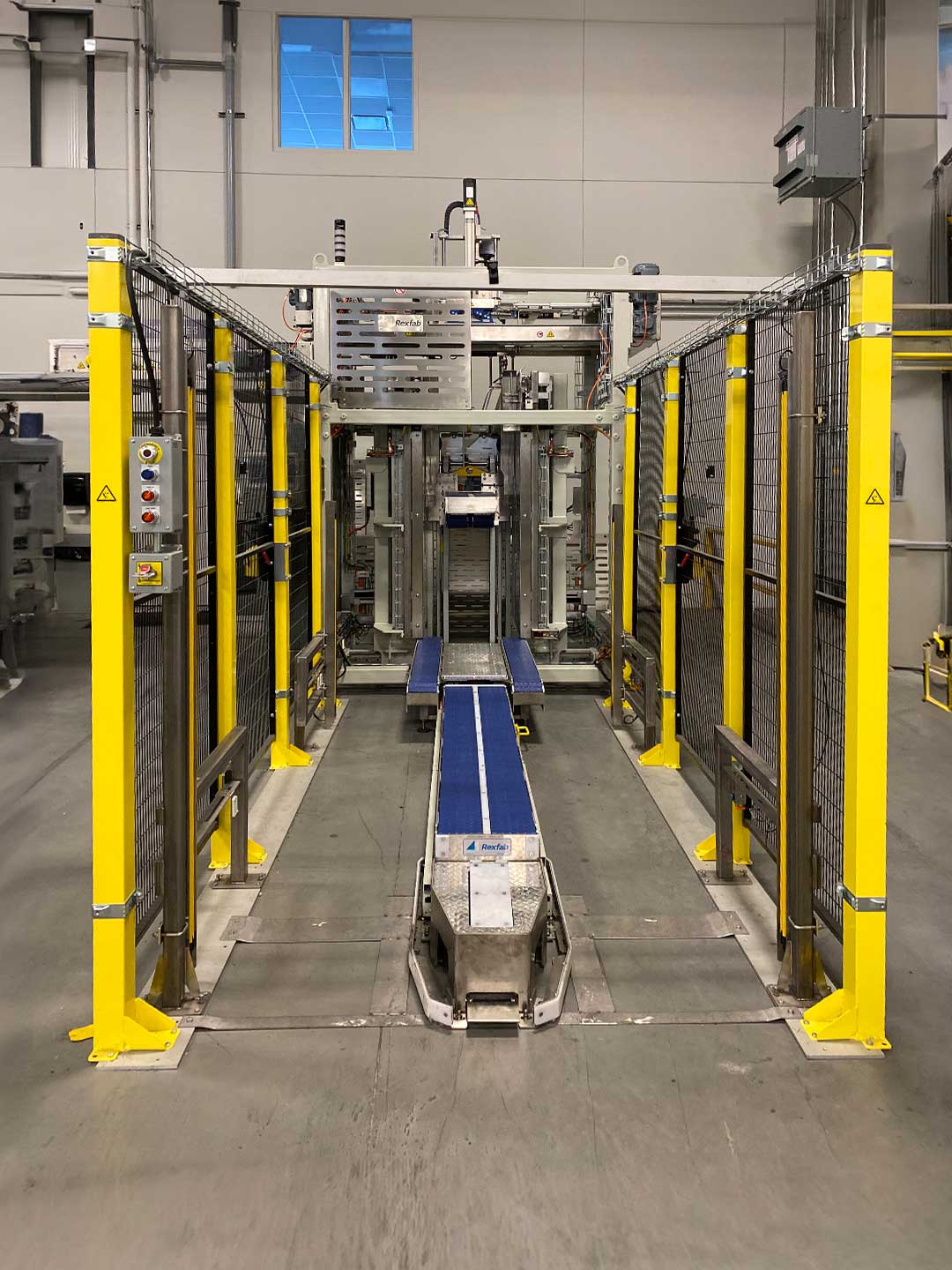

Electric actuators with electromagnets offer a compelling alternative to compressed air systems. By leveraging the precise control, high speed, responsiveness, reliability, and durability of electromagnet-based electric actuators, manufacturers can achieve significant improvements in operational efficiency and sustainability.

These advantages are particularly pertinent in the bakery and food industry, where precision, hygiene, and cost-efficiency are paramount.

Recommendations

1. Conduct Energy Audits: Bakery and food industry manufacturers should begin by conducting comprehensive energy audits to identify inefficiencies associated with their current compressed air systems. This data-driven approach will highlight areas where transitioning to electric actuators could yield the most significant benefits.

2. Phased Implementation: Gradually replacing compressed air systems with electric actuators can help manage costs and minimize operational disruptions. Prioritizing high-energy-use areas for early replacement can provide immediate efficiency gains and set a positive precedent for further changes.

3. Invest in Training and Awareness: Educate employees about the benefits of electric actuators and train them on best practices for maintaining and operating these systems. A well-informed workforce is crucial for maximizing the benefits of new technology.

4. Collaborate with Technology Providers: Partnering with technology providers who specialize in electric actuators and electromagnet technologies can facilitate the transition. These providers can offer tailored solutions, technical support, and ongoing innovations to meet the specific needs of the bakery and food industry.

5. Monitor and Optimize: Implement monitoring systems to continuously track the performance of electric actuators. Regularly reviewing and optimizing these systems will ensure they continue to deliver energy savings, cost reductions, and reliability improvements.

By adopting electric actuators with electromagnets, the bakery and food industry can enhance its operational efficiency, reduce costs, and contribute to a more sustainable manufacturing environment. This transition is not only a strategic response to the limitations of compressed air systems but also a proactive step towards achieving long-term sustainability and competitiveness in the market.

WE INVITE YOU TO KNOW MORE ABOUT REXBAF’S SOLUTIONS, OUR PAN STACKER PAN UNSTACKER IS A VIVID EXAMPLE OF THE USAGE OF ELECTROMAGNETS AND ALL THE ADVANTAGES THE USAGE OF THIS TECHNOLOGY PROVIDES.

Rexfab & Intralox: A Game-Changer for the Baking Industry

Rexfab, an expert in automation solutions for the baking industry, and Intralox, a global leader in innovative conveyor belt solutions, joined forces and have been working together to revolutionize production efficiency and product quality in the baking industry.

Strengthening Ties with PMMI: A Distinguished Visit to Rexfab

On August 22nd, Rexfab was honored to host Andrew Dougherty, VP of Member Services at PMMI. The visit allowed us to showcase our innovative solutions and learn more about PMMI’s vision for the future.

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.