Introduction:

Rexfab, an expert in automation solutions for the baking industry, and Intralox, a global leader in innovative conveyor belt solutions, joined forces and have been working together to revolutionize production efficiency and product quality in the baking industry. This partnership marks a milestone for bakeries of all sizes, this collaboration combines state-of-the-art conveyor and automation technology, streamlining operations from dough handling to packaging; optimizing operations, enhancing product quality and reducing costs; aiming to set a new standard, offering adaptable solutions to meet the industry’s ever-evolving needs.

Here, we’ll explore the unique benefits of this partnership, highlighting how Rexfab and Intralox’s combined strengths can redefine what’s possible in industrial baking.

1. Seamless Conveyor Technology with Tailored Solutions

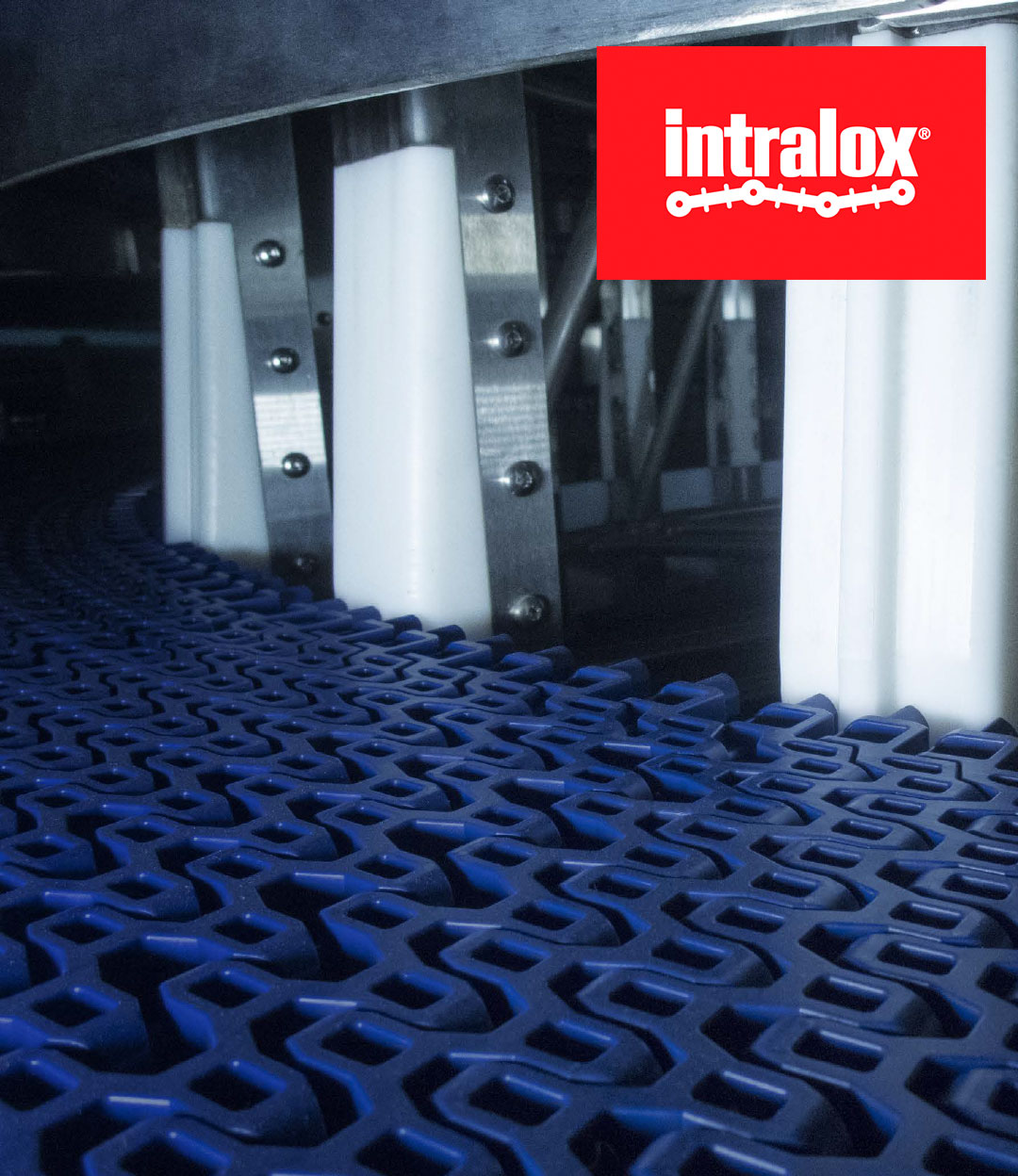

One of the standout features of this collaboration is the seamless integration of Intralox’s cutting-edge modular plastic conveyor belts with Rexfab’s automation and equipment solutions. Known for its precision, Intralox conveyor technology provides a highly efficient means of transporting baked goods through various stages of production, from dough preparation to packaging. By integrating with Rexfab’s specialized equipment, bakeries can expect a smoother, more efficient workflow that minimizes disruptions and maximizes throughput.

Key benefits:

Reduced Downtime

Intralox’s low-maintenance belts and easy-to-clean design help reduce stoppages, while Rexfab’s automation systems ensure a continuous production flow.

Enhanced Adaptability

Together, they offer customizable solutions to meet the unique needs of each bakery, whether producing large or small batches.

2. Advanced Hygienic Standards

Food safety and hygiene are top priorities for bakeries, and the Intralox-Rexfab partnership addresses these concerns head-on. Intralox’s hygienic conveyor systems and Rexfab’s clean-in-place (CIP) capabilities ensure that products meet the highest sanitary standards without sacrificing efficiency.

Key benefits:

Faster Sanitation

With easy-clean designs, sanitation becomes quicker and less labor-intensive, minimizing downtime.

Enhanced Food Safety

Reduced risk of contamination helps bakeries adhere to strict regulatory standards, protecting both products and customers.

3. Increased Efficiency through Automation

Rexfab brings extensive expertise in automation, helping bakeries streamline operations and reduce manual labor. This is particularly valuable in an industry that often faces labor shortages. By automating repetitive tasks, bakery production lines become more efficient, allowing employees to focus on higher-value tasks.

Key benefits:

Higher Throughput

Automation of repetitive tasks boosts output without requiring additional staff.

Consistent Quality

Automated processes deliver uniformity, reducing waste and ensuring each product meets quality expectations.

4. Scalable Solutions for Growing Businesses

This partnership empowers bakeries of all sizes, from artisanal shops to large-scale production facilities, to grow confidently. The scalable solutions from Rexfab and Intralox mean that businesses can expand their capabilities over time, all while using the same trusted technology.

Key benefits:

Cost-Efficiency

Scalable technology means bakeries can add equipment and conveyors as their production needs increase without a complete overhaul.

Flexible Production

Companies can shift production to meet seasonal or sudden demand spikes, maximizing profitability.

5. Lower Total Cost of Ownership (TCO)

Thanks to their low-maintenance designs, the products offered through the Rexfab-Intralox partnership reduce the total cost of ownership. Intralox’s durable belts and Rexfab’s reliable equipment extend the life cycle of production assets, resulting in a better return on investment for bakery businesses.

Key benefits:

Extended Equipment Life

Durable, high-quality components mean fewer replacements and a longer equipment lifespan.

Reduced Maintenance Costs

Reliable, low-maintenance designs mean less downtime and lower overall maintenance expenses.

Conclusion

By merging top-tier conveyor technology with innovative automation, this collaboration provides the baking industry with a future-ready approach to meet rising consumer demands.

The Rexfab-Intralox partnership is a win-win for the baking industry, for bakeries looking to improve hygiene standards, boost efficiency, and scale production seamlessly, this collaboration offers unparalleled value.

Embrace the future of baking with the Intralox-Rexfab partnership – where advanced technology meets unmatched industry expertise to help your business rise to new heights.

WE INVITE YOU TO KNOW MORE ABOUT REXBAF’S SOLUTIONS AND ALL THE ADVANTAGES THE USAGE OF OUR EQUIPMENT PROVIDES.

CONTACT US NOW!

Strengthening Ties with PMMI: A Distinguished Visit to Rexfab

On August 22nd, Rexfab was honored to host Andrew Dougherty, VP of Member Services at PMMI. The visit allowed us to showcase our innovative solutions and learn more about PMMI’s vision for the future.

CAROLINA FOODS QUALITY SERVICE AND SCALABILITY THROUGH INNOVATION

Dan Myers, CEO of Carolina Foods, provides some insight on the baking company’s new facility in Pineville, NC and the opportunities for expanded capabilities it will present upon completion.

ELECTROMAGNETS AND ITS IMPACT ON THE BAKERY FOOD INDUSTRY

Compressed air systems are ubiquitous in manufacturing environments, serving as a power source for pneumatic tools, conveyors, and automation systems. Despite their widespread use, these systems are notoriously inefficient, with energy losses that translate into higher operational costs and environmental burden. As industries strive for sustainability and cost-effectiveness, re-evaluating the role of compressed air in manufacturing becomes imperative.