REXFAB COMPANY OVERVIEW

PIERRE MEUNIER, P.ENG., President

Pierre started the Rexfab adventure 14 years ago. He’s always looking ahead and is committed to giving his clients the best service possible. Every decision is made with people in mind and he strives to make Rexfab a leading service company where people love to work.

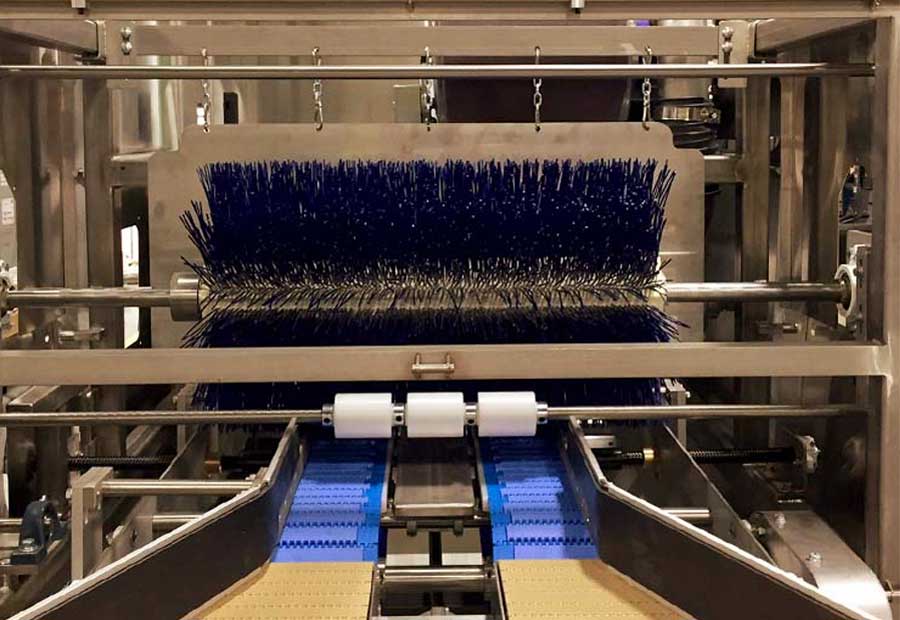

POST-BAKING AUTOMATION SOLUTIONS

AUTOMATED SOLUTIONS

Rexfab automates downstream production processes, allowing bakeries to increase efficiencies while decreasing labor costs.

ADVANCED ANALYTICS

Rexfab can’t predict your bakery’s future, but we’re getting close by implementing AI and data collection throughout food manufacturing operations.

ABOUT US

At its heart, Rexfab is a people company. Yes, we make automated systems, but what makes us different is our commitment to client success and safety.